Impumlo yokondla ngomgubo

1. Impumlo yokondla umgubo we-coaxial oneendlela ezintathu/ezine: umgubo uphuma ngqo kwindlela ezintathu/ezine, udibene kwindawo enye, indawo yokuhlangana incinci, ulwalathiso lomgubo aluchaphazeleki kangako ngumxhuzulane, kwaye ulwalathiso lulungile, lufanelekile kwi-laser Restoration enemilinganiselo emithathu kunye nokuprinta kwe-3D.

2. I-annular coaxial powder feeding nozzle: Umgubo ufakwa ngemijelo emithathu okanye emine, kwaye emva konyango lwangaphakathi lwe-homogenization, umgubo uphuma kwisangqa kwaye udibana. Indawo yokuhlangana inkulu kakhulu, kodwa iyafana ngakumbi, kwaye ifanelekile ngakumbi ekunyibilikeni kwelaser eneendawo ezinkulu. Ifanelekile kwi-laser cladding ene-angle yokuthambekela ngaphakathi kwama-30°.

3. Impumlo yokutyisa umgubo osecaleni: isakhiwo esilula, ixabiso eliphantsi, ukufakelwa kunye nokulungiswa okulula; umgama phakathi kweeplagi zomgubo ude kakhulu, kwaye ulawulo lomgubo kunye nokukhanya lungcono. Nangona kunjalo, umqadi welaser kunye nokufakwa komgubo azilingani, kwaye ulwalathiso lokuskena lulinganiselwe, ngoko ke alunakuvelisa umaleko ofanayo wokugquma nakweyiphi na indlela, ngoko ke alufanelekanga ukugquma nge-3D.

4. Impumlo yokondla umgubo omile okwebha: igalelo lomgubo kumacala omabini, emva konyango lwe-homogenization yimodyuli yokukhupha umgubo, umgubo omile okwebha ophumayo, kwaye uqokelele kwindawo enye ukuze wenze indawo yomgubo omile okwebha eyi-16mm*3mm (enokwenziwa ngokwezifiso), kunye nokudibanisa okufanelekileyo kwamabala anomtya anokufezekisa ukulungiswa komphezulu we-laser enkulu kwaye kuphucule kakhulu ukusebenza kakuhle.

Isixhobo sokuhambisa umgubo

Iiparameter eziphambili ze-feeder ye-powder yebhareli ephindwe kabini

Imodeli yesondlo somgubo: EMP-PF-2-1

Isilinda yokondla ngomgubo: ukondla ngomgubo wesilinda ezimbini, i-PLC ezimeleyo elawulekayo

Imo yoLawulo: tshintsha ngokukhawuleza phakathi kokulungisa iimpazamo kunye nemo yokuvelisa

Ubukhulu: 600mmX500mmX1450mm (ubude, ububanzi kunye nokuphakama)

I-Voltage: 220VAC, 50HZ;

Amandla: ≤1kw

Ubungakanani besuntswana yomgubo othunyelwayo: 20-200μm

Isantya sediski yokondla ngomgubo: 0-20 rpm ummiselo wesantya ongenamagxa;

Ukuchaneka kokuphinda ukondla ngomgubo: <±2%;

Umthombo wegesi ofunekayo: I-nitrogen/Argon

Abanye: Ujongano lokusebenza lunokwenziwa ngokwezifiso ngokweemfuno

I-Laser Pyrometer

Ulawulo lobushushu oluvaliweyo, olufana nokucima nge-laser, ukugquma kunye nonyango lomphezulu, lunokugcina ngokuchanekileyo ubushushu obuqina bemiphetho, iiprotrusions okanye imingxunya.

Uluhlu lobushushu bovavanyo luqala kwi-700℃ ukuya kwi-2500℃.

Ulawulo oluvaliweyo, ukuya kuthi ga kwi-10kHz.

Iiphakheji zesoftware ezinamandla ze

ukuseta inkqubo, ukubonisa, kunye

ukugcinwa kwedatha.

Iiterminal ze-l/O zemizi-mveliso ezine-24V yedijithali kunye ne-analog 0-10V l/O yomgca ozenzekelayo

ukuhlanganiswa kunye noqhagamshelo lwe-laser.

Iingenelo zokugquma nge-laser

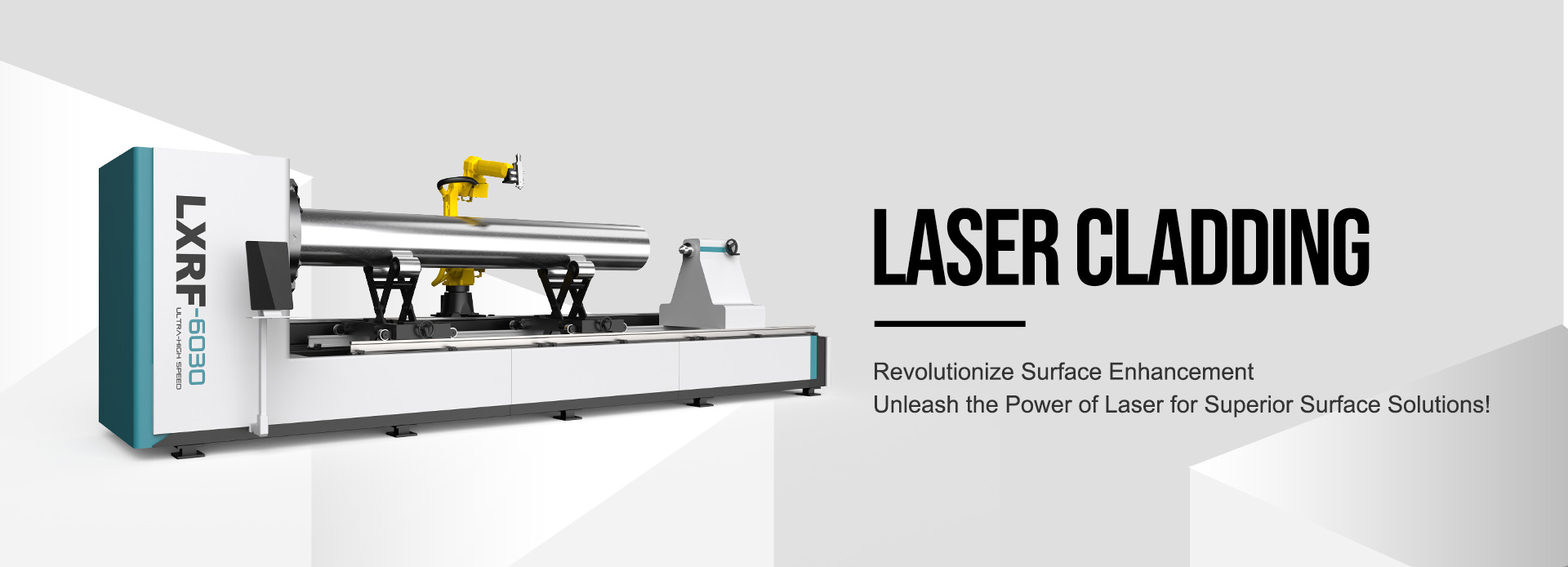

Izicelo zeLaser Cladding

●Kwishishini leemoto, ezifana neevalvu zenjini, ii-cylinder grooves, iigiya, izihlalo zeevalvu zokukhupha umoya kunye nezinye iindawo ezifuna ukumelana nokuguguleka okuphezulu, ukumelana nobushushu kunye nokumelana nokugqwala;

●Kwishishini leenqwelo-moya, ezinye iipowder ze-alloy zigqunywe phezu kwe-alloys ze-titanium ukusombulula ingxaki ye-alloys ze-titanium. Iingxaki ze-coefficient enkulu yokungqubana kunye nokumelana nokuguguleka okubi;

●Emva kokuba umphezulu wesikhunta kwishishini lesikhunta uphathwe nge-laser cladding, ubulukhuni bawo bomphezulu, ukumelana nokuguguleka, kunye nokumelana nobushushu obuphezulu kuyaphucuka kakhulu;

●Ukusetyenziswa kwe-laser cladding kwimiqulu kwishishini lentsimbi kuye kwaxhaphaka kakhulu.